- Add.: Tangxia Road, Taihexian Industrial Park, Ji'an City, Jiangxi Province

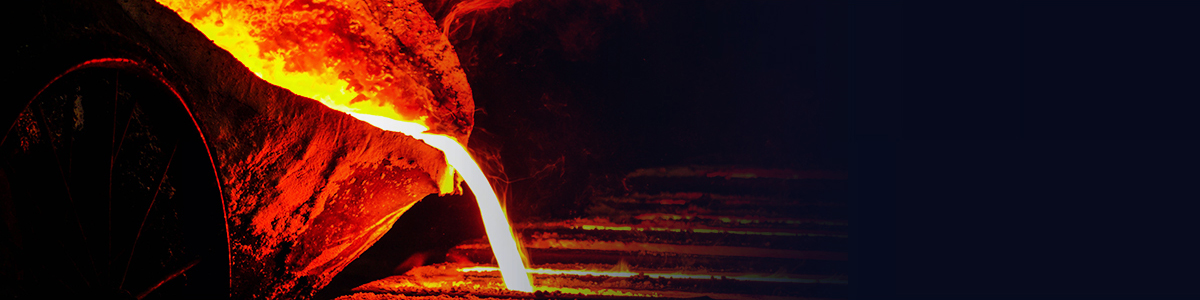

HXZR Skimming Machine for Melt Furnace

The skimming machine for melt furnaces is suitable for ammonia removal and slag removal of aluminum, zinc and copper in crucible furnaces, bath furnaces, reverberatory furnaces, ladles and static tanks.

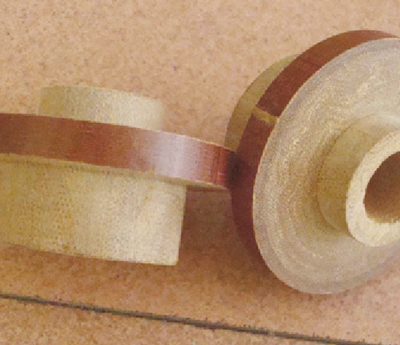

The working rotor inside the melt furnace skimmer will break inert gases (argon or nitrogen( within the molten aluminum, zinc, and copper into a larger amount of dispersed bubbles that absorb hydrogen and oxidized slag in the solution that needs to be removed from the molten metal surface as the bubble rises. This is carried out based on the partial pressure difference between gas and the surface adsorption principle, thus purifying the melt.

Since the bubbles are finely dispersed and uniformly mixed with the rotating melt, there will be no air flow generated in contact with the melt via the continuous straight rise as the bubbles slowly rotate and float up in a spiral shape, thus significantly improving the purification effects. Both argon and nitrogen with the purity over 99.95% can degas the aluminum liquid.

Hongxing Corporation has been designing and manufacturing industrial furnace/ovens and heat treating equipment since 2006.Our products cover all types of melting and holding furnace or heat treatment equipment.