- Add.: Tangxia Road, Taihexian Industrial Park, Ji'an City, Jiangxi Province

Changing stone color through electrolysis is an essential operation for stone product manufacturers, allowing them to customize stones according to their customers.

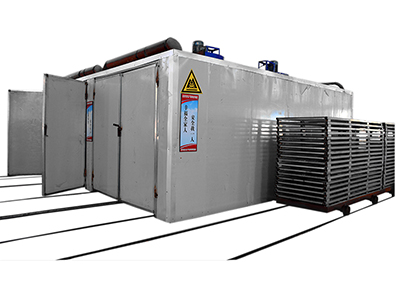

In the past, blanks would be heated and solidified by conventional ovens heated by coal or electric. This was a difficult process to control and led to a high scrap rate for these blanks. In response to this issue, Hongxing designed a track for feeding and discharging the workpieces according to the characteristics of their color changes and transferring properties.

The heat treatment equipment adopts a PLC central control system and features trolleys and track frames in the oven with a load capacity up to 100 tons. The rectangular heat treating furnace is easy to operate, safe and convenient to use. The equipment is eco-friendly as there are no chemicals and dyes added in the coloring process. It can be customized according to daily output and stone size.